-

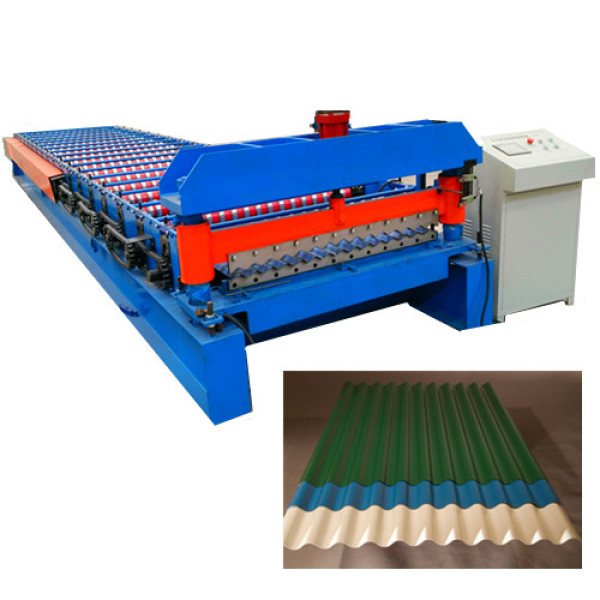

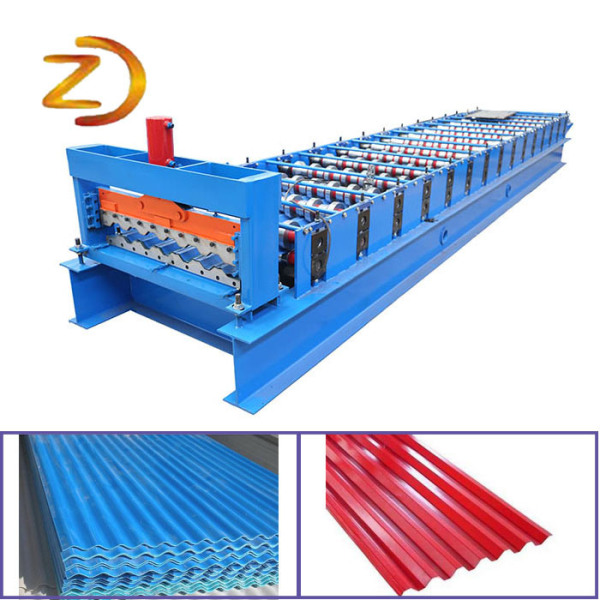

Color coated roof sheet forming machine

-

Corrugated roof panel roll forming machine

-

Corrugated roof roll forming machine

-

Corrugated iron roller machine

-

Corrugated iron sheet roll forming machine

-

Corrugated iron sheet rolling machine

-

Metal Sheet Corrugated Zinc Roof Steel Making M...

-

Corrugated metal roof panel machine

-

Corrugated Iron Sheet Roof Roll Forming Machine

-

Corrugation Galvanized Roof Steel Forming Machine

-

Galvanized Corrugated Zinc Sheet Metal Roll For...

-

Corrugated Wall Cladding Panel Forming Machine

-

Corrugated Metal Roof Rolling Forming Machine

-

Corrugated Metal Panel Roll Former Machine

-

Aluminium Steel Corrugated Sheet Forming Machine

-

Corrugated iron Roof Forming Machine

-

Aluminum roof sheet roll form mill

-

Color coated roof sheet machine

-

Corrugating Iron Sheet Roll Forming Making Machine

-

Roof Sheet Corrugated Automatic Cold Roll Formi...

-

Corrugated Metal Sheet Automatic Tile Making Ma...

-

Metal corrugation wall panel roll former machine

-

Corrugated sheet rolling machine

-

Corrugated iron making machine